Description

BY USING ION EXCHANGE RESINS, YOU CAN REPLACE THE MINERAL SALTS IN WATER

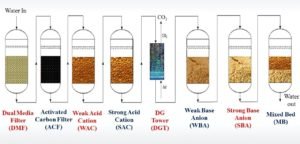

Demineralization is the process of removing ionic minerals from water. While it can refer to all water-purification processes that remove minerals, the term demineralization is designated to only those processes that remove near total amounts of ionic minerals. Mineral ions such as cations of sodium, calcium, iron, copper, etc and anions such as chloride, sulphate, nitrate, carbonate, bicarbonate etc are common ions present in water. It is common for deionization and demineralization to be used interchangeably.

In the context of water purification, ion-exchange is a rapid and reversible process in which impurity ions present in the water are replaced by ions released by an ion-exchange resin. There are two types of resins – anion exchange resins and cation exchange resins. The former resin releases hydroxyl ions, which are negatively charged ions. The cation resins release hydrogen ions which are usually positively charged ions. The impurity ions are taken up by the resin, which must be periodically regenerated to restore it to the original ionic form.