Description

It is high time we must follow the concept of three R’s (reduce, reuse and recycle water) for the well-being of our planet and our future generations. We can reduce water wastage by using it wisely.

In the industrial sector, wastewater is generated according to the impurities involved in their own specific applications or processes. Any wastewater treatment process is designed to protect the environment, to reduce impurities below the local pollution standards, and to meet application requirements.

Water reuse, also known as water recycling or reclaimed water, is the process of collecting and treating wastewater, storm water, saltwater, or greywater for use in domestic consumption, industrial processes, surface or ground water replenishment, and watershed restoration. When compared to seawater desalination, the term municipal wastewater reuse commonly refers to the process of tertiary treatment followed by desalination, which produces potable water from wastewater at a fraction of the cost

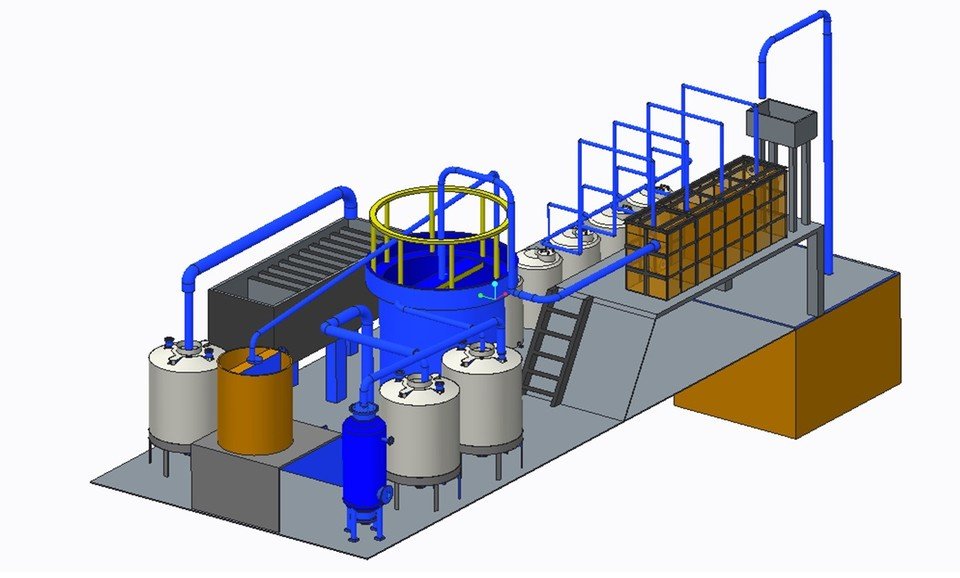

Effluent treatment plant (ETP) is a process design for treating the industrial wastewater for its reuse or safe disposal to the environment. It removes contaminants such as suspended and di ssolved solids, organics, inorganics, oil and grease, colour, heavy metals from industrial wastewater. The removal of these contaminants is achieved through physical, chemical, and biological processes which produce effluent that is safe enough for discharge into the environment as per government regulations or which can also be reused for various industrial processes based upon the quality of water required.

How does ETP plant work?

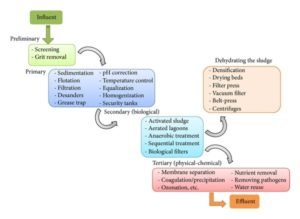

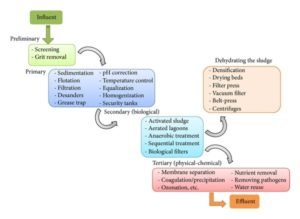

Treatment levels:

- Preliminary – physical separation of big sized impurities like cloth, plastics, wood logs, paper logs etc

- Primary – removal of floating and settleable materials such as suspended solids and organic matter

- Secondary– to remove or reduce the concentration of organic and inorganic compounds

- Tertiary (advanced) –final cleaning process that improves wastewater quality before it is reused, recycled or discharged to the environment

In the conceptual approach to the treatment, particles are removed from the water, organic matter is dissolved, and sludge is handled for disposal. Different processes involved are:

Screening: A screen with openings of uniform size is used to remove floating materials which are visible to eyes such as plastics, cloth etc.

Equalisation: The purpose of equalization tanks is to balance the raw effluent from various processing units. An existing mixed effluent tank is used to collect wastewater, which is then pumped to an existing aeration tank, which also functions as an equalisation tank.

pH control : The pH of wastewater is modified using pH neutralization. The pH of an acidic waste solution can be modified by adding bases. Alkali waste (high pH) is treated with acids to lower its pH.

Coagulation: Refers to collect the minute solid particles dispersed in a liquid into a larger mass. Chemical coagulants like aluminium sulphate or ferrous sulphate are added to wastewater to improve the attraction among fine particles so that they come together and form larger particles called flocs that are easily removed through settling and filtration. The purpose of the agitator for wastewater treatment is to create certain hydraulic conditions to make all colloidal particles complete the flocculation process in the shortest time.

Sedimentation: Physical wastewater treatment process using gravity to remove suspended solids from water. The particles that gather at the bottom of a container are called sludge.

Anaerobic Processes: The anaerobic treatment processes take place in the absence of air (oxygen). It utilizes microorganisms (anaerobes) which do not require air (molecular/free oxygen) to assimilate organic impurities. The final products are methane and biomass. In the anaerobic process, the decomposition of organic matter of the effluent is performed by feeding anaerobic microorganisms, and four successive biological processes are involved including hydrolysis, acidogenesis, acetogenesis, and methanogenesis

Aerobic Processes: Aerobic treatment processes take place in the presence of air (oxygen). It utilizes those microorganisms (aerobes), which use molecular/free oxygen to assimilate organic impurities i.e. convert them into carbon dioxide, water and biomass.

Secondary clarification: The purpose of secondary clarification is to return activated sludge after the biological treatment procedure. The biomass from microorganisms settles to the bottom in the form of activated sludge during the secondary clarifying phase. The biomass of microbes is returned to the aeration tank after settling for a period of time, and the cycle is repeated until the effluent is clean before being sent for filtering and/or disinfection. Prior to the digesting process, waste sludge is removed and thickened.

Filtration: A filter removes particulates from wastewater as it passes through it. These filters must be backwashed regularly to keep them clean.

Disinfection: Bacteria, viruses and parasites, which are harmful to public health, are removed by using chlorine

Sludge management system: It is the process of transforming sludge into useful products. Removal of water reduces storage volume and transportation costs. It significantly reduces the volume and weight of the sludge so that it is easier to recover.