Description

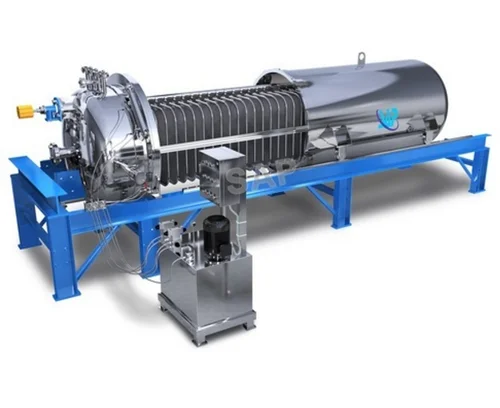

Suitable for batch process applications with high flow rates and low solid removal, horizontal leaf filters provide superior performance. A horizontal pressure leaf filter comes with a horizontal tank and a removable lid. As a seal between the framing joint and the cover, a spacer is used, which is tightened by turning a bayonet-type ring with two hydraulic cylinders of the valve. In addition, the cover is taken off by means of the hydrocylinder. The horizontal vessel orientation is the most common type of pressure leaf filter. This arrangement allows for the greatest filtration area. All horizontal filters use vertical filter leaves.

Horizontal pressure leaf filters can be fully automated and are enclosed filtration systems. After clarification, this filter produces a high clarity filtrate and can also be used for all kinds of filter aids. The regeneration time between the filtration cycles is short. Additionally, horizontal pressure leaf filters can be delivered as tandem units to reduce floor space requirements. Since there are no rotating parts in the pressure leaf filter, maintenance is minimal. These advantages result in an economical filtration solution.