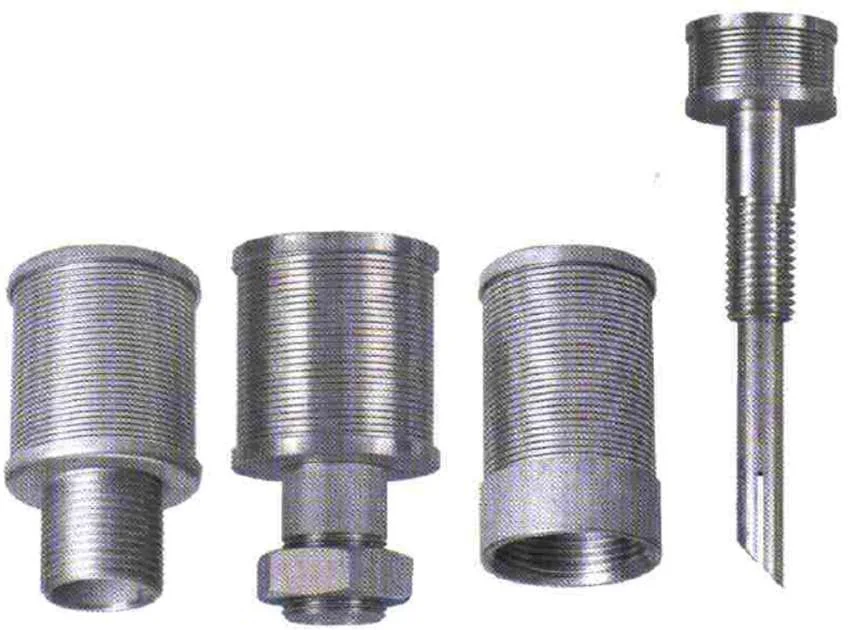

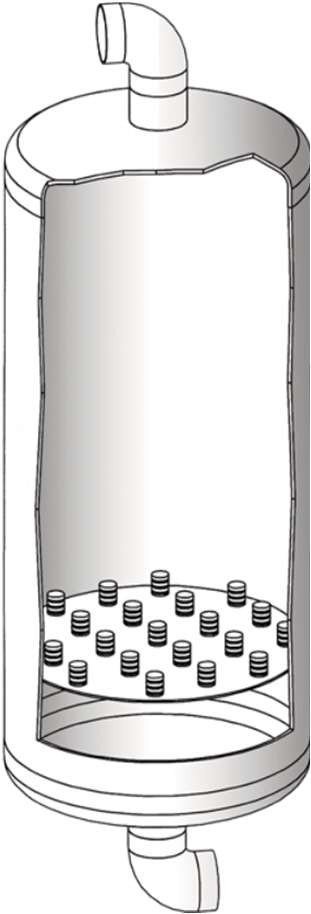

Description

Nozzles, Laterals & Resin Traps are basically filtration/retention components used in Ion-Exchange Columns. The main purpose of the nozzles and laterals is to keep the resins inside the column while allowing only the fluid to pass through. In case there is some leakage from the column then the resin traps are used as safety traps in the pipe lines just after the column. Owing to continuous operation of columns high reliability is expected from these components as any leak of resins will lead to untimely shut-down of the units causing heavy losses and high maintenance costs of downstream equipment. With apt design expertise the nozzles and laterals can be designed to avoid channelling effect and dead- zones in media bed.