Description

The Pressure Sand Filter/Multigrade Sand Filter is a depth filter that employs a predetermined percentage of coarse and fine material. This setup creates a filter bed with big enough pore sizes to hold both large and small suspended particles. This filter has a far greater specific flow rate than traditional filters, and it is the most often used method for removing turbidity from water. The Pressure Sand Filter is made up of several layers of sand of various sizes and specific gravity. These filters are made to remove turbidity and suspended particles from feed water with the least amount of pressure drop possible. These Filters are custom designed to suit the process requirement.

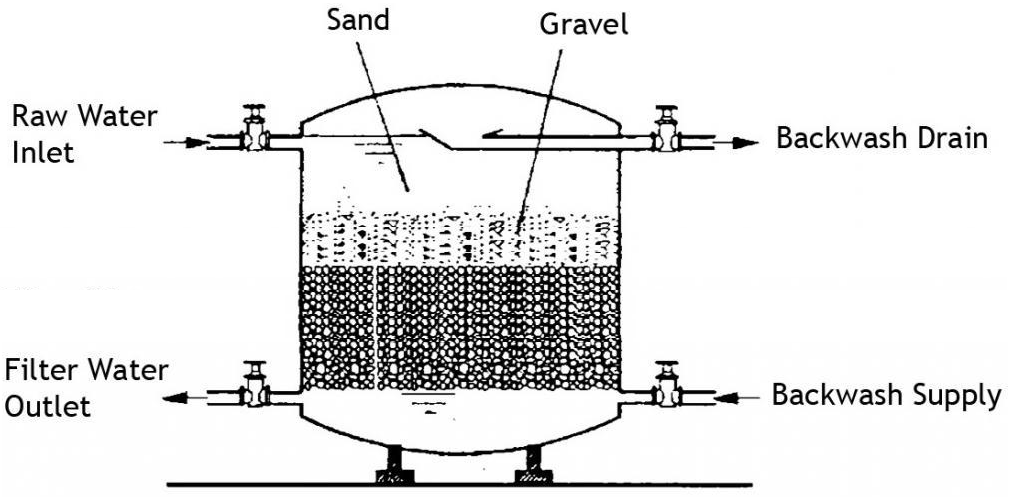

A pressure sand filter is made up of a vertical or horizontal pressure vessel with a set of frontal pipe work and valves, graded silica quartz sand supported by layers of graded under bed consisting of pebbles and gravels, a top distributor to distribute the incoming water uniformly throughout the cross section of the filter, and an under drain system to uniformly collect the filtered water.