Description

With a semipermeable membrane, you can safely and economically purify domestic & industrial water

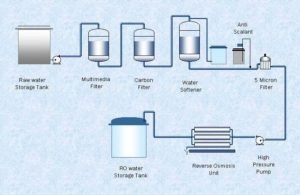

A reverse osmosis (RO) system uses a membrane to remove dissolved solids and ions from solutions. When solution is on one side of a membrane, pressure is applied to remove these dissolved solids and ions. Therefore, the solute is retained on the pressurized side of the membrane, while the pure solvent passes through. For reverse osmosis, the polymer matrix in the membrane has a dense layer where separation is most effective. The technology improves the quality and safety of water for domestic as well as for the industrial purposes. The need to dispose treated effluent to such an extent that it can be recycled and then reused back in the process grows urgent as waste disposal rules become more stringent. In most cases, an RO plant requires pre-treatment to prevent membrane fouling/scaling due to sediments, hardness, organic matter, bacteria, silica, or metal oxides.