Description

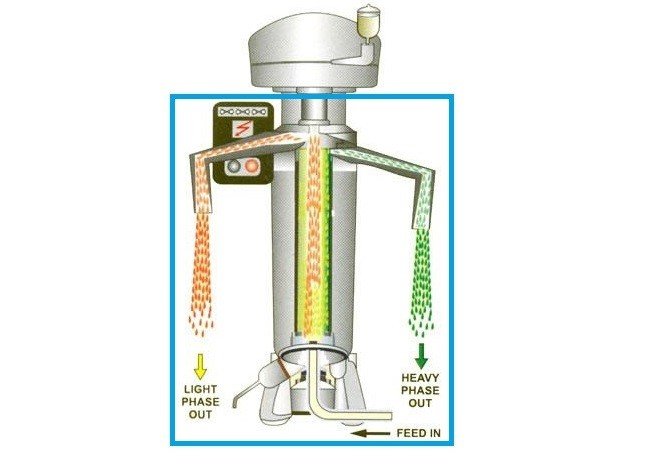

Although it is sometimes used as a batch centrifuge, the tubular centrifuge is generally utilised for the continuous separation of liquids from liquids or very small particles from liquids. When larger centrifugal fields are necessary for separation, it is typically used. A tubular centrifuge’s revolving bowl is made up of a long hollow tube (length many times its diameter). The feed or material to be centrifuged enters at one end near the axis and is withdrawn in two streams holding the separated material for continuous separation.

The interior structure of the tube can be designed in a variety of ways, but radial vanes are commonly used to speed up the feed material and slow down the divided streams before they are discharged. A high-speed motor powers the centrifuge. As the fluid moves from one end of the tube to the other, sedimentation occurs. The solid material is frequently allowed to deposit on the wall when the heavy material comprises of very small particles or molecules and the concentration is very low. The machine is used as a batch centrifuge in this scenario.